Highlights:

Saskatoon, SK, Canada, April 10, 2025 – Core Nickel Corp. (CSE: CNCO) (“Core Nickel” or the “Company”) is pleased to announce the results of the re-analysis of twelve historical diamond drill holes (“DDH”) from the Company’s 100%-owned Mel project (the “Project”) in the Thompson Nickel Belt, Manitoba. The resampling program was completed, in part, to verify historical assay results and help define methods and the overall approach for an updated National Instrument 43-101 mineral resource estimate. Understood Mineral Resources (“UMR” or “Understood”) was retained by Core Nickel to confirm historical nickel assay results.

The Mel project encompasses the Mel deposit (“Mel”), which is characterized by a historical mineral resource consisting of an indicated resource of 4,279,000 tons grading 0.875% Ni, plus an inferred resource of 1,010,000 tons grading 0.839% Ni, at a cut-off of 0.5% Ni.1

Misty Urbatsch, Chief Executive Officer, President, and Director of Core Nickel, commented, “We are very encouraged by the re-assay results as it confirms both the integrity of the historical data and high-grade core of the deposit. This gives us added confidence in the quality and accuracy of the historical resource as well as provides a solid foundation as we move toward a modern mineral resource estimate. Highlights such as 1.73% Ni over 36.3 metres and 2.81% Ni over 11.6 metres reflect the strength and continuity of mineralization at the Mel deposit. Based on the confirmation from the re-assay results, Mel has the potential to be one of the highest-grade undeveloped nickel deposits in North America.

Located just 20 kilometres from key infrastructure, including existing mines, mills with available capacity, rail access, and nearly 100% renewable hydroelectric power—Mel is well-positioned for further advancement as we continue to evaluate its development potential. Historical drilling at Mel over the past 50 years has focused on shallow depths averaging only 200 metres, with the near-surface deposit originally discovered in the 1960s at a depth of just 50 metres. The recently completed VTEM survey over Mel will help us image down to 400 metres depth and provide a better understanding of the geology at depth. While previous exploration has primarily targeted near-surface mineralization, we see compelling potential below 200 metres, particularly given that the neighbouring Thompson Mine operates at depths exceeding 1,000 metres within a similar geological setting.”

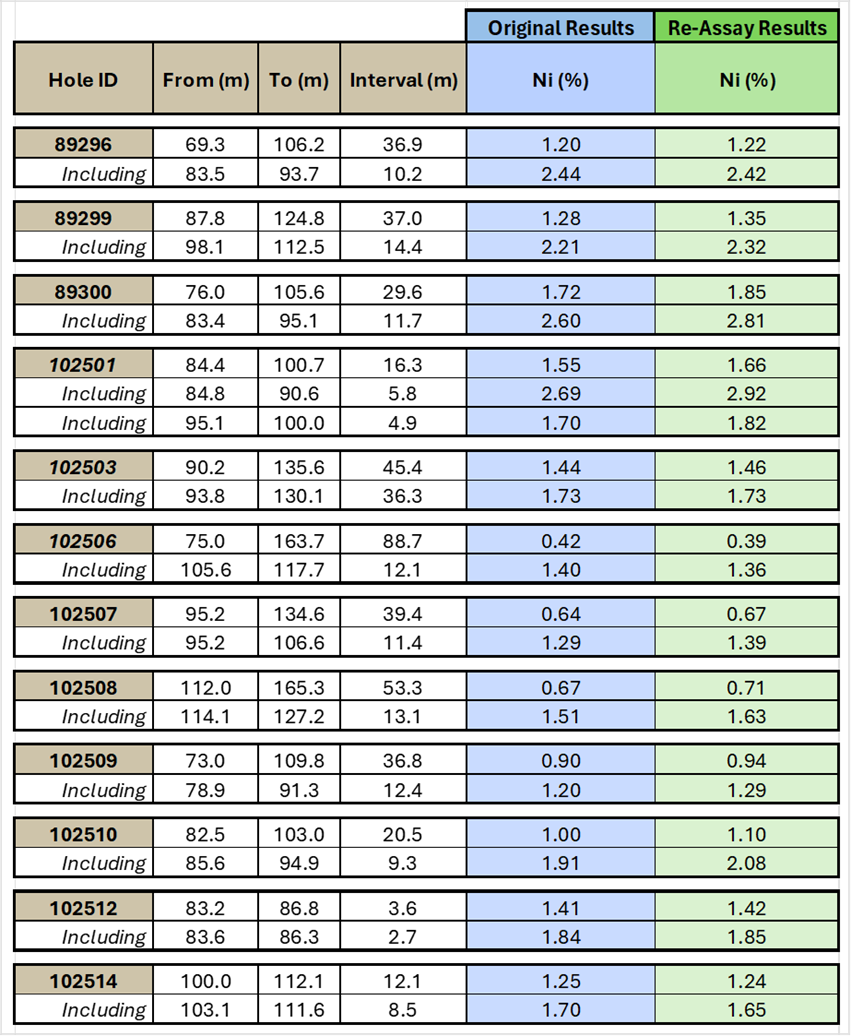

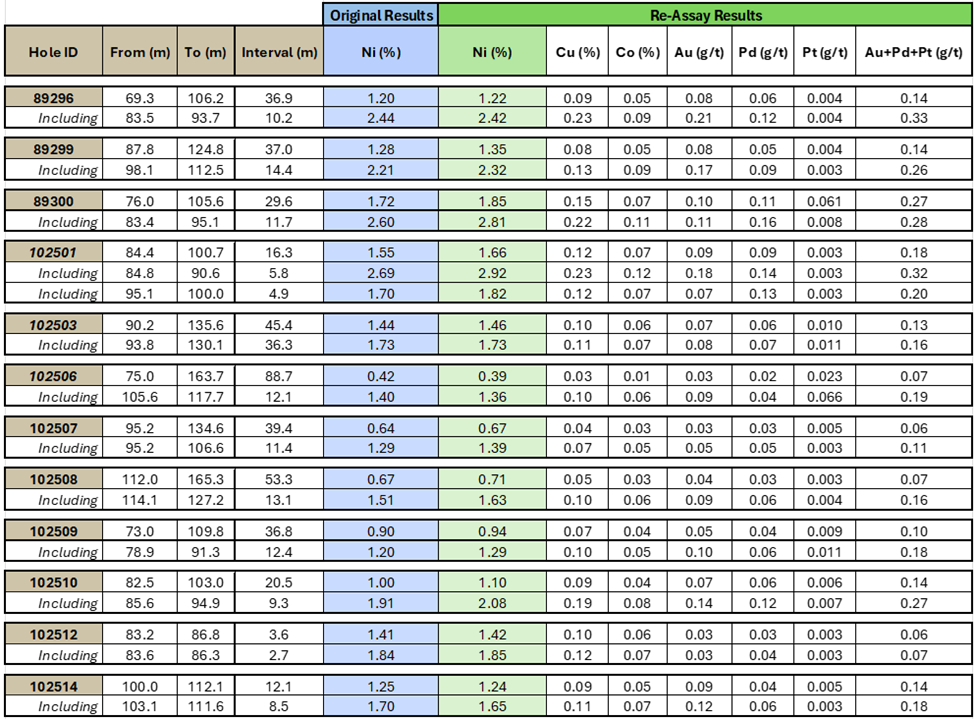

Table 1. Comparison of Original and Re-Assay Nickel Results

Confirmation of Historical Nickel Results

The nickel results from the resampling program were compared against the historical data through a variety of statistical techniques. It was determined the resampling results correlate well with the historical data and no meaningful bias was identified between the two datasets.

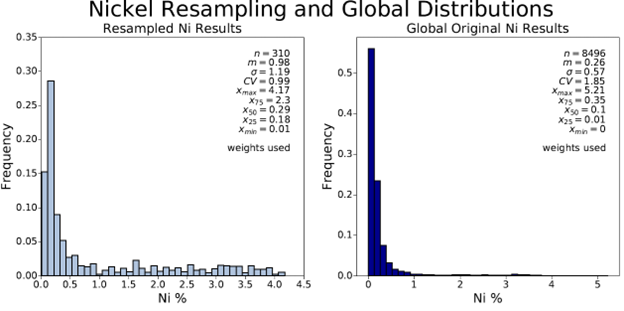

The resampled nickel grades were compared to the global original distribution (nickel grades of the entire deposit) to ensure representative grade ranges were selected for reanalysis (Figure 1). The histograms in Figure 1 show the selected samples are an appropriate representation of grades observed at the deposit.

Figure 1. Resampled and Global Original Nickel Histograms

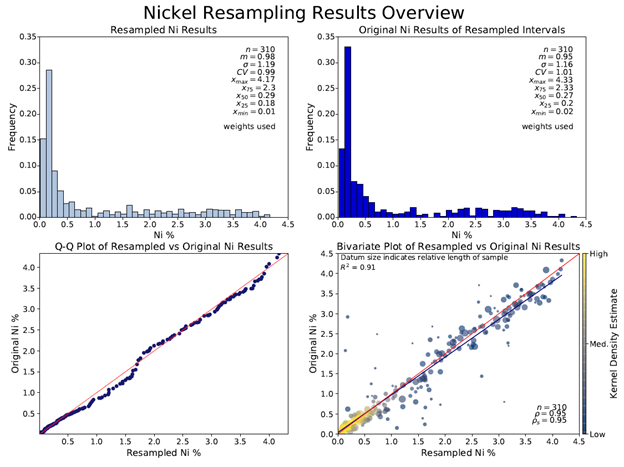

The historic and resampled results of the individual intervals were compared to validate the precision and accuracy of the historical results through histograms, quantile-quantile (Q-Q) plots, and scatter plots (Figure 2).

The two histograms (sample length weighted) and the summary statistics displayed in the histograms, such as mean, variance, min values, and max values, are nearly the same between the two distributions.

The Q-Q plot shows that the two distributions generally correlate with no significant bias. A Q-Q plot is a plot of the quantiles of two distributions against each other for comparison purposes.

The scatter plot and contained summary statistics demonstrates the datasets generally correlate and agree with one another: the blue trend line plots near the red reference line, a high Pearson correlation coefficient ( ), a high coefficient of determination (R2 = 0.91), and no apparent grade-dependent bias.

Figure 2. Resampling and Original Nickel Results by Interval

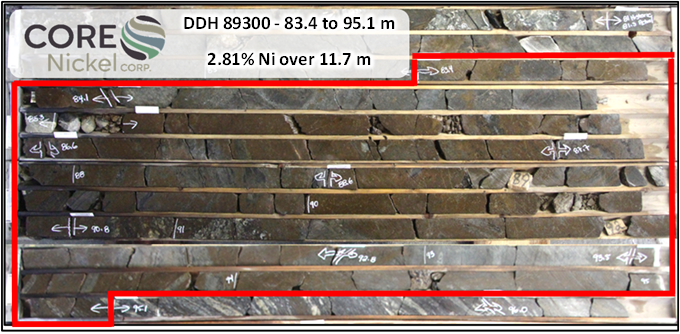

Figure 3: Nickel Intercept from Drillhole 89300 (2.81% Ni over 11.7 m)

Figure 4. Nickel Intercept from Drillhole 102503 (1.73% Ni over 36.3 m)

Mel Re-Assay Program

The Company selected previously sampled mineralized NQ core for re-analysis and maintained the sample intervals defined by the historical assays (also referred to as original results). The interval ranges between 0.1 m to 3.7 m with an average of 1.35 m. The samples were collected from previously halved NQ core that was further split into quarter core. The quarter core was placed in plastic sample bags pre-marked with the sample number along with a sample number tag. The other quarter was returned to the core box for long-term storage. The bags containing the split samples were then placed in rice bags with zip ties for transport to the Saskatchewan Research Council Geoanalytical Laboratories (“SRC”) in Saskatoon, Saskatchewan, by Core Nickel personnel.

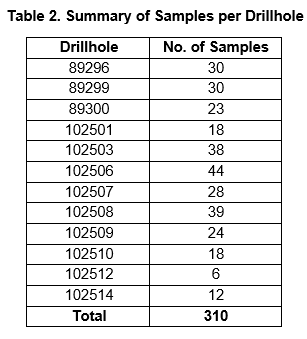

In total, 310 samples from 12 drill holes were collected and analyzed (Table 2). Core Nickel inserted 17 blank samples and 17 certified reference material samples into the sample stream for quality control and quality assurance (QA/QC) purposes.

The samples were analyzed at SRC using a base metal assay (ICP3 Assay) for Ni, Cu, and Co, where an aliquot of sample pulp is digested in HCl:HNO3 and the digested volume is then made up with deionized water for analysis by inductively coupled plasma optical emission spectroscopy (ICP-OES). The detection limit for Ni, Cu, and Co using this method is 0.001 wt%.

The samples were also analyzed for gold, platinum, and palladium using traditional fire assay methods. During fire assay an aliquot of sample pulp was mixed with standard fire assay flux in a clay crucible and a silver inquart was added. The mixture was fused in a fire assay oven. The fusion melt was poured into a metal form and cooled. The lead bead was recovered and put into the oven for cupellation until only the precious metal bead remained. The bead was parted in a solution heated in a boiling water bath until the silver dissolved. The solution containing the silver was decanted, leaving the gold, platinum, and palladium in the test tube. Aqua Regia was added to the gold, platinum, and palladium in the test tube and heated in the boiling water bath until the metals dissolved. The sample was diluted to volume and analyzed by ICP-OES. This method is suitable for all pulverized and core samples for the determination of gold. The detection limit for Au, Pt, and Pd using this method is 1 ppb. The Au, Pd, and Pt grades were converted from ppb to grams per tonne.

Table 2. Summary of Samples per Drillhole

Table 3. Complete Re-assay Results from Historical Mel Core

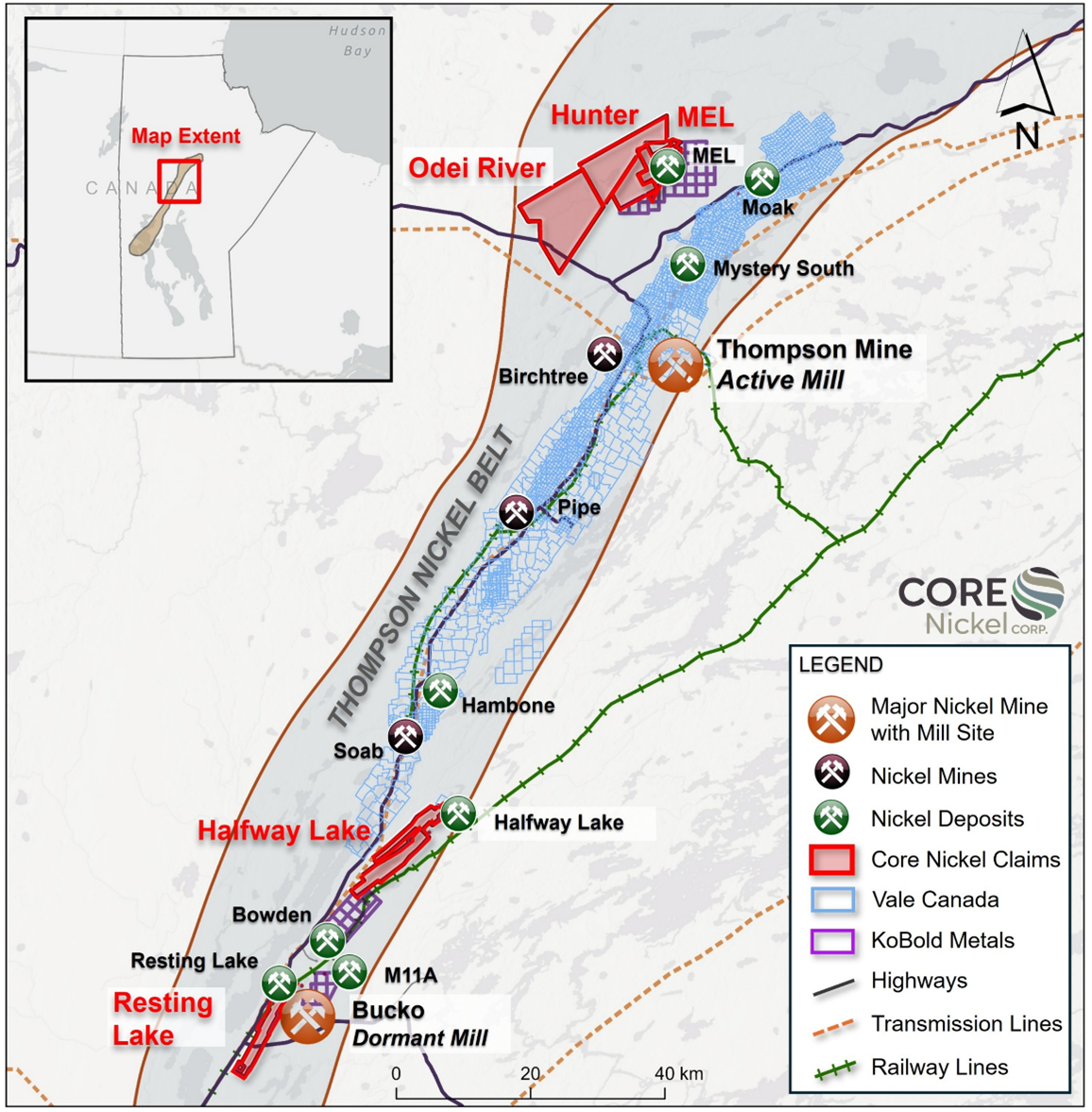

About Core Nickel

Core Nickel Corp. is a junior nickel exploration company that controls 100% of five projects in the Thompson Nickel Belt (TNB), a prolific nickel district located in Northern Manitoba, Canada (Figure 5). The five projects consist of approximately 27,000 hectares of land that is proximal to existing infrastructure, including highways, railways, major hydroelectric transmission lines, and operating mills.

Core Nickel has a large contiguous land package in the northern part of the TNB, situated approximately 15-20 km from the City of Thompson. Core Nickel’s northern TNB land package consists of three projects: Mel, Hunter, and Odei River. The Mel project encompasses the Mel deposit, which is characterized by a historical mineral resource consisting of an indicated resource of 4,279,000 tons grading 0.875% Ni, plus an inferred resource of 1,010,000 tons grading 0.839% Ni, at a cut-off of 0.5% Ni.1 The target stratigraphy (Pipe Formation) that hosts the Mel deposit, and other deposits in the Thompson Nickel Belt, extend onto the Hunter and Odei River projects and drillhole intersections into the target stratigraphy on the Hunter project have successfully intersected anomalous nickel.

The Company also holds two projects in the central TNB near the community of Wabowden: Halfway Lake and Resting Lake. Both projects host the target Pipe Formation associated with known elevated nickel mineralization and are proximal to existing nickel deposits, mills, and other infrastructure.

Figure 5. Core Nickel Project Location Map

The Qualified Person under National Instrument 43-101 Standards of Disclosure for Mineral Projects for this news release is Caitlin Glew, P. Geo., Vice-President Exploration for Core Nickel Corp., who has reviewed and approved its contents.

References

1 (n.d.). https://www.canickel.com/satellite-deposits#satellited

2 “Technical Report on the Mel Deposit, Northern Manitoba” prepared for Victory Nickel Inc, Shane Naccashian (P. Geo.) of Wardrop Engineering Inc., March 9, 2007

Mel Historical Mineral Resource

Core Nickel Corporation is treating the 2007 Mineral Resource Estimate (MRE) prepared for Victory Nickel Inc. by Shane Naccashian (P. Geo.) of Wardrop Engineering Inc. as a “historical mineral resource” under National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and the reader is cautioned not to treat it, or any part of it, as a current mineral resource. Core Nickel has not done sufficient work to classify the historical estimate as a current mineral resource.

The historical MRE summarized above has been included simply to demonstrate the mineral potential of the Mel deposit and the Mel project. Core Nickel considers the 2007 MRE to be relevant to the further development of the project; however, is not treating the historical estimate as a current mineral resource. The historical MRE was calculated in accordance with NI 43-101 and CIM standards at the time of publication and predates the current CIM Definition Standards for Mineral Resources and Mineral Reserves (May, 2014) and CIM Estimation of Mineral Resources & Mineral Reserves Best Practices Guidelines (November, 2019).

To upgrade or verify the 2007 historical estimate as current, Core Nickel will need to complete a thorough review of all the 2007 historical MRE information and drill data, along with the incorporation of subsequent exploration work and results, which includes some drilling around the edges of the historical MRE subsequent to the publication of the resource. Additionally, a full review of the economic parameters utilized to determine current Reasonable Prospectus for Eventual Economic Extraction (RPEEE) would be required in order to produce a current MRE for the Property. Any future mineral resource will need to evaluate the open pit and/or underground potential taking into consideration the current cost and pricing conditions or constraints, along with continuity of the resource blocks.

Technical Disclosure

The historical results contained within this news release have been captured from Manitoba Integrated Mining and Quarrying System (“iMaQs”) as available and may be incomplete or subject to minor location inaccuracies. Management cautions that historical results were collected and reported by past operators and have not been verified nor confirmed by a Qualified Person but form a basis for ongoing work on the subject projects.

On behalf of the Board of Directors

“Misty Urbatsch”

Misty Urbatsch

CEO, President and Director

Core Nickel Corp.

Contacts:

| Misty Urbatsch, CEO and President | General Enquiry |

| Tel: 306-668-6927 | Tel: 306-668-6927 |

| Email: [email protected] | Email: [email protected] |

Also find us online:

Neither the Canadian Securities Exchange nor its regulations services accept responsibility for the adequacy or accuracy of this release.

Forward-looking information

All statements included in this press release that address activities, events or developments that the Company expects, believes or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements involve numerous assumptions made by the Company based on its experience, perception of historical trends, current conditions, expected future developments and other factors it believes are appropriate in the circumstances. In addition, these statements involve substantial known and unknown risks and uncertainties that contribute to the possibility that the predictions, forecasts, projections and other forward-looking statements will prove inaccurate, certain of which are beyond the Company’s control. Readers should not place undue reliance on forward-looking statements. Except as required by law, the Company does not intend to revise or update these forward-looking statements after the date hereof or revise them to reflect the occurrence of future unanticipated events.